Accessories, Cargo Terminals, CARE, Ground Handlers, Safety

In’s and Out’s of Pallet Couplers

History does not seem to have recorded when somebody first decided to connect together a couple of PMC pallets in order to transport some oversize cargo, however today it is not uncommon for operators of main deck freighters to utilize pallet couplers for various applications and cargo types.

On the surface, a simple enough piece of equipment, inexpensive to purchase, simple to install. Indeed what is there not to like about using a pallet coupler rather than the much more expensive and often logistically challenging 20 feet pallet? But, as is so often the case, the devil is in the details and this article will explore the key safety and compliance issues that cannot be ignored.

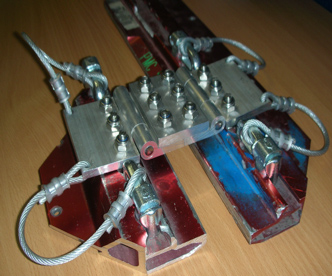

What do we mean by pallet couplers? Unlike most other ULD items or accessories, there is very little in the way of formal specifications for pallet couplers and it is most likely that the design of any couplers in service today has evolved from some early “hands on” fabrications, with probably influence from military air cargo operations where couplers are also used.

While not having to follow any particular standard, the common components will be some kind of hinging device to allow vertical movement between coupled pallets along with a mechanism that enables the couplers to be attached to the seat track of the coupled pallets. Not particularly costly to purchase, these devices may well appear to be an easy way to avoid the cost and logistics issues that come with 16/20 ft. pallets.

While not having to follow any particular standard, the common components will be some kind of hinging device to allow vertical movement between coupled pallets along with a mechanism that enables the couplers to be attached to the seat track of the coupled pallets. Not particularly costly to purchase, these devices may well appear to be an easy way to avoid the cost and logistics issues that come with 16/20 ft. pallets.

But things are not as simple as they appear:

- To consider pallet couplers, it is necessary to understand the manner in which pallets are secured to the aircraft cargo loading system (CLS). Although large pallets are frequently described as 20 feet pallets they are actually not 20 feet long, but are in fact 238.5” or 1.5” short of 20 ft. (the “16” foot pallet is in fact 16 ft. 4” long). Compare these dimensions to those of a PMC which are 125” long. So if these pallets laid end to end reach 250”, or 20 ft. 10”- this is considerably longer than the so called “20 ft. “ pallet.

- The design the restraint system used to secure 20 feet pallets (and 16 feet pallets) on main deck freighters is completely different from that used to secure PMC pallets. Unlike the system used for PMC where the CLS uses side guides and pallet locks to secure the pallet around all 4 sides, 16 and 20 ft. pallets are secured only along their long sides with no restraint directly onto the short end of the pallet.

It is therefore absolutely impossible to secure coupled PMC pallets in the aircraft’s 16/20 ft. locking system (and conversely not possible to secure a 16/20 ft. pallet in the lock system for PMC).

- If the coupled pallets cannot be secured in the same way as a 20/16 ft. pallet how can they be safely secured in the aircraft? This is where things get rather challenging, for two major reasons:

- Firstly, it can generally be said that the use of pallet couplers is not mentioned in Weight and Balance manuals. In the absence of any mention as to how to use these devices, it is then up to the operator to assess a safe manner for the use of these devices and to provide the required procedures in the airline’s manuals, if they choose to do so.

- Secondly, while the only correct manner to carry a PMC pallet on the aircraft is for all 4 sides of the pallet to be secured against both vertical and horizontal movement by the locks and stoppers of the CLS, when 2 pallets are coupled together, it is not physically possible to raise the pallet locks along the sides that are coupled- the geometry of a pallet lock is such that it cannot be raised and positioned between two coupled pallets.

NOT POSSIBLE WITH COUPLED PALLETS- Therefore in the absence of an acceptable manner by which both the PMC pallets can be secured on all 4 sides, and with contents in the applicable Weight and Balance Manual, the only correct manner in which coupled pallets can be used is in a “non-ULD” or floating configuration, where the pallets are only being used to support and move the cargo from the cargo terminal to on board the aircraft, but where 100% of the cargo restraint is through direct tie down to the aircraft structure following prescribed tie down calculations and procedures.

Four more points to consider when thinking about pallet couplers:

- So far this article has addressed the use of couplers with PMC pallets. In fact the same principles that apply to PMC pallets also apply to PAG size pallets. The industry also does use couplers to connect 2 ea. 20 ft. pallets to create a 40 ft platform. In general the size and nature of a 40 ft. load will mean it is carried on the center line of the aircraft and is secured with straps directly to the aircraft floor, removing any likelihood of incorrect restraint of the coupled pallets.

- There is no possibility of using nets with coupled PMC pallets- any kind of net arrangement will not be compatible with the pallet/net certification.

- For pallet couplers to be able to engage in the seat tracks of the coupled pallets, there needs to be an exact alignment across the gap between the seat track cut outs and this can only be assumed where the two pallets are of the same manufacture and part number.

- If pallets are coupled, then they should always move in a straight line and avoid any kind of turning as this will place excessive stress on the couplers and the pallet seat track and can result in a breakage.

The use of pallet couplers has evolved over the years in somewhat of a regulatory vacuum. The IATA ULD Regulations Section 6/03 contains some material on the subject; some airlines may have developed their own rules for the use of pallet couplers, but the bottom line is that unless the Weight and Balance Manual of the specific aircraft provides a manner in which coupled pallets may be secured in the cargo loading system, then a coupled pallet shall only be considered and used as a floating pallet with the cargo restrained directly to the aircraft structure.

The recently published preliminary investigations into the National Air Cargo B747F crash in Afghanistan 2 years ago includes mention that a pair of coupled pallets loaded with some general cargo was on board the aircraft. While there is nothing at this stage that indicates that this item played any part in the accident, it does mean that the use of coupled pallets is now under increased scrutiny.