Basics, Cargo Terminals, Freight Forwarders, CARE, Ground Handlers, ULD Service providers

Life limitations of ULD

The question “what is the life of a ULD” is asked quite frequently and until recently the answer was generally fairly simple: “as long as you want to keep repairing it”.

However this is no longer the case and the whole issue of what is the safe life for a container, pallet, net and cargo strap is now subject to a whole new set of rules. In this article we will endeavor to cast some light on this often confusing aspect of ULD.

One only has to spend a few minutes looking at pallet nets or fabric container doors to realize that there seems to be a lack of standards when it comes to the condition of this equipment. As one will quickly find, nets and other fabric components that look to be well and truly worn out are still being used. This situation is about to start changing, with the introduction of life limitations on any materials used in ULD that may degrade from exposure to Ultra Violet light and/or any other environments that may reduce the strength of the material.

Actually the requirement for cargo nets to be “lifed” to take into account degradation is nothing new. The IATA ULD Technical Manual has for many years contained a recommendation that nets should be designed with a 1.25 lifing factor (e.g. extra strength) so that even after degradation has taken place the net will still meet its required strength. However this was not reflected in the certification requirements and since a 1.25 lifing factor added weight and cost, many nets never had this provision built in.

The recent changes are the result of a very extensive investigation by EASA over a number of years whereby sample nets of various ages were collected from various airlines for testing by an independent test facility in Germany. It is beyond the scope of this article to go into the details of the testing methods but the conclusion reached by EASA gave them sufficient cause for concern to raise this issue to higher levels including sharing their findings with the US FAA.

We now see the results of these findings appearing in the form of regulations:

- Any new ULD design under TSO C90d (which now applies to all new design submissions) being submitted to the authorities for approval must now demonstrate through calculations or testing that the environmental degradation of any non-metallic components, which for instance can be fabric cord in nets, composite panels in a container or PVC door covers in a ULD, shall have a defined life.

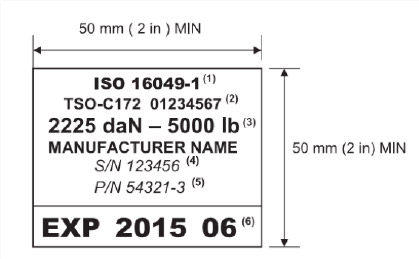

- All cargo straps certified under TSO C172 shall have a defined service life after which they may no longer be used.

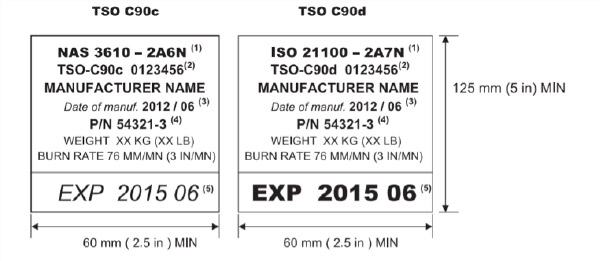

- The IATA ULD Regulations (Standard Specification 50/2) now require (with effect from 01 Jan 2014) that all new nets be marked with an expiry date, whether the net is certified under TSO C90 c or TSO C90 d.

These new requirements have not gone down too well with some parts of the industry, as airlines suddenly recognize that their expenditure, particularly on cargo nets, will be considerably higher if they follow these rules. But the industry only has itself to blame for this inconvenience. It was only after the authorities recognized that insufficient care was being taken in managing the condition of textile items in ULD that these rules were imposed; and once imposed, they are going to be here to stay.

There are obviously some practical considerations to working with these new requirements, including:

- How to identify the expiry date of a textile item.

- For components used on a container such as a door or composite panel, the process is to be handled at the workshop level. It is not expected that front line operators will have to asses if the different parts of the container are within their life limit.

- For cargo nets new labeling is now mandatory under the IATA ULD Regulations:

While for cargo straps labeling is also required :

While for cargo straps labeling is also required :

It must be expected that checking for equipment that has passed its expired date becomes second nature just as any other part of a ULD check process and that the approach of “let’s use it one more time” becomes a thing of the past. The IATA standard for a strap ODLN includes a requirement to check the expiry date before use and this can also be expected to be added to net ODLN’s before long.

- Shelf life of unused (new) nets and straps is a concern for many operators, whose purchasing patterns may mean that stocks are held on the shelf at the airline for weeks and months before entering service. In the past some airlines developed systems whereby a net’s expiry date could be marked on the net at the time it entered service, thus eliminating any time spent in storage, however the authorities have made it clear that the only expiry date marked on the item shall be a date put there by the manufacturer and no other party is permitted to mark an expiry date. This means that the clock starts ticking down to expiry from the moment the net is delivered from the factory, the authorities have permitted the OEM’s to add a nominal additional period of a few months into the defined life of the net to allow for this transit/storage period, but that’s that, no further concessions are permitted and if an airline inadvertently leaves a stock of nets on the shelf for the entire life of the nets then that’s bad luck, they may not be used.

There is no question that these new requirements represent both a financial challenge to the industry at a time when everyone is looking to cut back on expenditure and an operational challenge when outsourcing of most cargo operations is widespread, but this is a non-negotiable safety issue, brought about by the authorities finding that the current industry practices were falling far short of acceptable levels and taking the steps they felt necessary to rectify this situation.

(Illustrations courtesy IATA ULD Regulations)

While for cargo straps labeling is also required :

While for cargo straps labeling is also required :